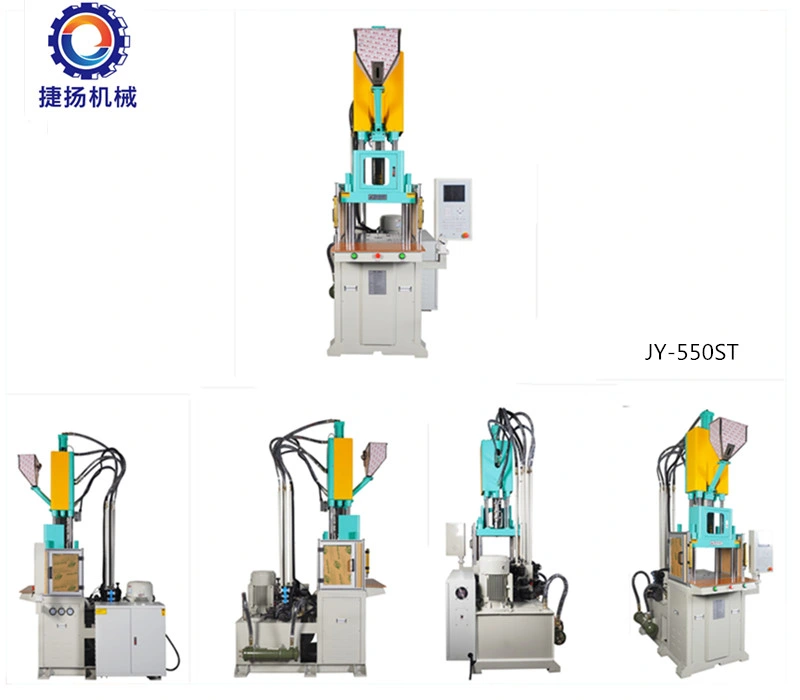

55 tons injection molding machine for PVC/PP/PET/TPU plastic

Function:

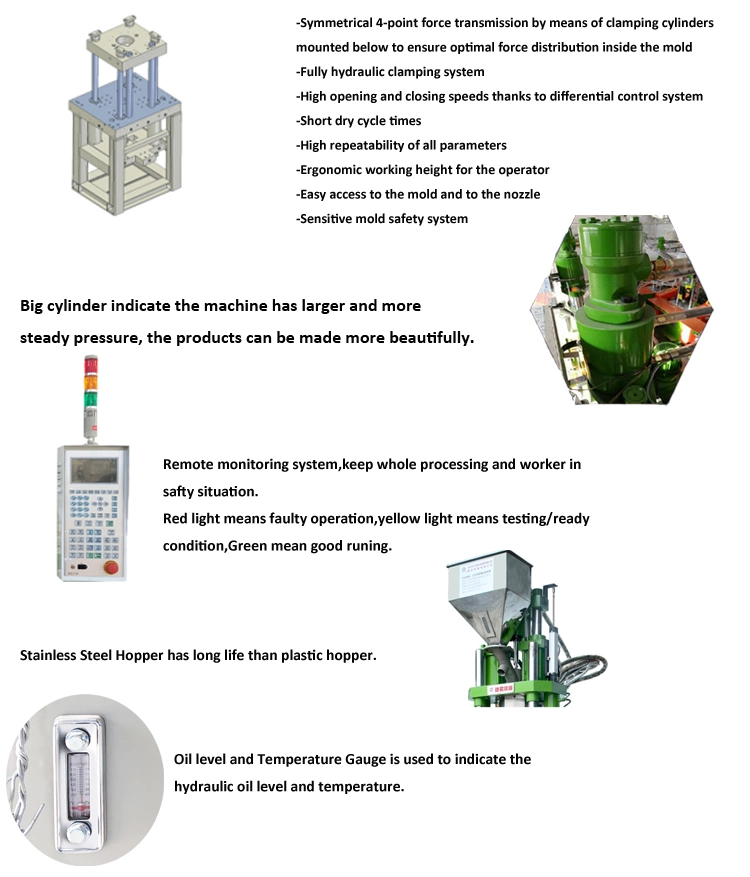

1. Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding.With double slide table or rotary design, put-in, take-out products and molding finish

at the same time, which is more safe and efficient for production , then reduce the cost of production.

2. High precision mold platen ( Parralelism/ flatness : 0.01/100mm), heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life.

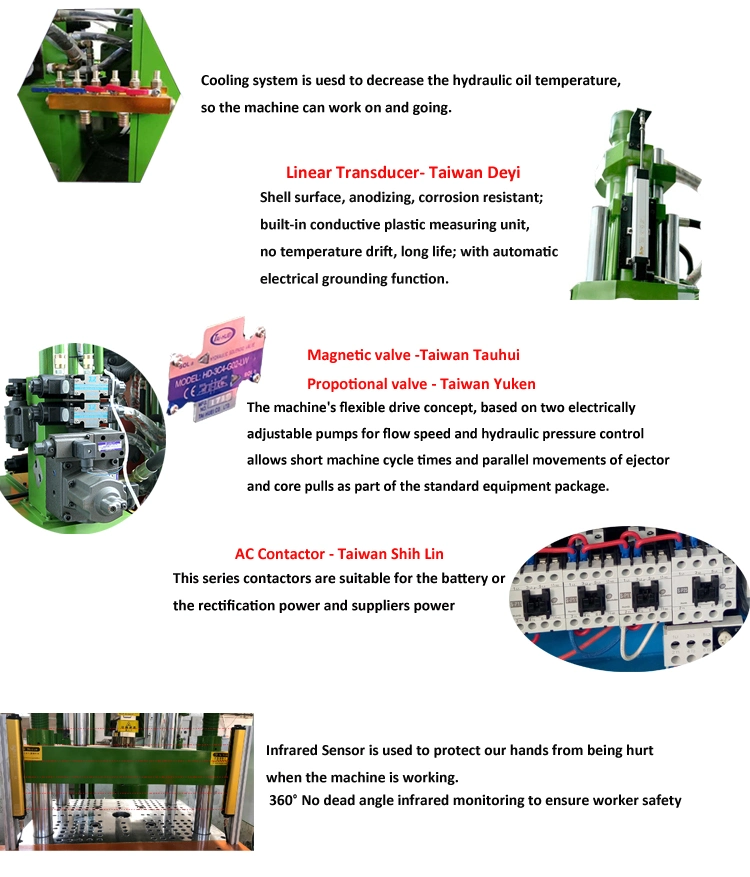

3. Nitride and NIP/ Nitroflon coated screws and barrels are longlasting, robust and provide superior acid/alkaline resistance.Heavyduty double cylinder injection unit is maintenance friendly and free of oil leaks.

4. All series adapted Variable pump +PQ valves enable energy savings of 30~50%.

5. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life.

Packing & Shipping :

1. Before shipping,we will check and test the machine carfully.

2. We will arrange to manufacture the second day after confirmation,we can delivery it usually after 25 days.

3. According to the destination,we will compare several transportation companies and select the most suitable

and economic one to provide service for us

FAQ:

Q1: Are you a trading company or a manufactory?

A1: We own a factory ourselves, and we can assure the quality we manufactured.

Q2:What's your guarantee or the warranty of the quality if we buy your

machines?

A2:We offer you high quality machines with high quality afterservice. Also we have

one year warranty of the spareparts, free of charge.

Q3: Why choose Jieyang Machinery Co.,Ltd.?

A3: Our products with more than 30% energy saving. Highest Cost effective

environmentally. Excellent pre-sale and after-sale services.

Function:

1. Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding.With double slide table or rotary design, put-in, take-out products and molding finish

at the same time, which is more safe and efficient for production , then reduce the cost of production.

2. High precision mold platen ( Parralelism/ flatness : 0.01/100mm), heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life.

3. Nitride and NIP/ Nitroflon coated screws and barrels are longlasting, robust and provide superior acid/alkaline resistance.Heavyduty double cylinder injection unit is maintenance friendly and free of oil leaks.

4. All series adapted Variable pump +PQ valves enable energy savings of 30~50%.

5. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life.

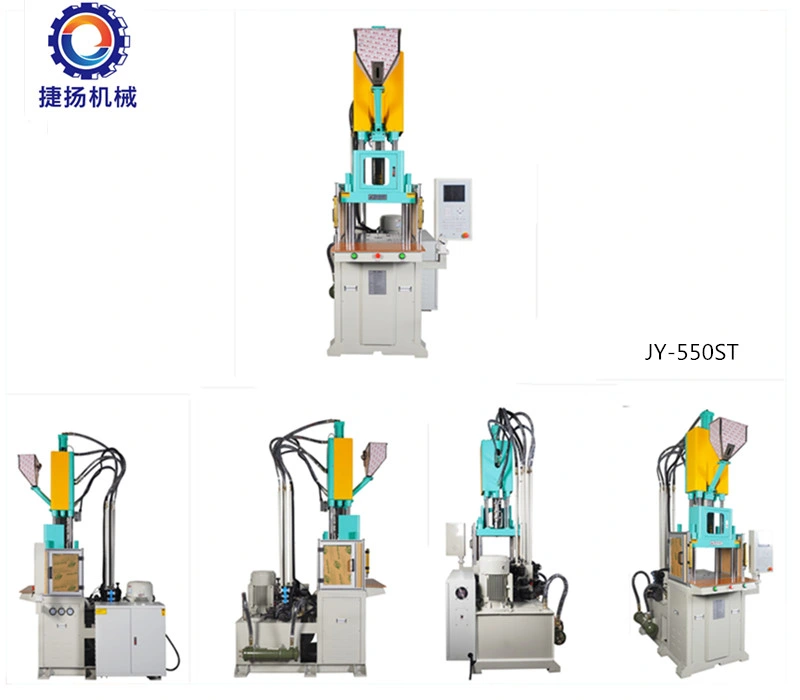

| Model | Unit | JY-550ST | ||

| Screw Barrel Diameter | mm | 32 | 34 | 42 |

| Injection Pressure | kg/cm2 | 1642 | 1385 | 960 |

| Max. Shot Weight | gram | 102 | 123 | 176 |

| Max. Shot Weight | cm3/sec | 49 | 59 | 84 |

| Screw Barrel Route | mm | 140 | ||

| Screw Barrel Rotary Speed | rpm | 0-175 | ||

| Nozzle Contact Force | tons | 5.5 | ||

| Nozzle Retraction Nozzle | mm | 210 | ||

| Number of Temperature Control | pcs | 3 | ||

| Clamping Force | tons | 55 | ||

| Platen Size | mm | 670*480 | ||

| Distance Between Tie Bere | mm | 470*280 | ||

| Min. Mold Height | mm | 270/70 | ||

| Opening Stroke | mm | 200 | ||

| Max. Opening Mold Distance | mm | 470/270 | ||

| Ejetor Force | tons | 1.76 | ||

| Ejetor Stoke | mm | 35 | ||

| Max. Hydraulic Pressure | kg/cm2 | 140 | ||

| Pump Output | L/min | 40 | ||

| Oil Resservoir Capacity | Liter | 150 | ||

| Cooling Water Consumption | L/hr | 800-1000 | ||

| Pump Motor Power | kw/hp | 7.5/10HP | ||

| Barrel Heating Power | kw | 4.5 | ||

| Total Power | kw | 12 | ||

| Machine Weight | tons | 3 | ||

| Machine Dimension(LxWxH) | meter | 1.85*1.2*3 | ||

| Shipping Weight | tons | 2.5 | ||

| Shipping Measurements(LxWxH) | meter | 1.945*1.35*2.44 | ||

Packing & Shipping :

1. Before shipping,we will check and test the machine carfully.

2. We will arrange to manufacture the second day after confirmation,we can delivery it usually after 25 days.

3. According to the destination,we will compare several transportation companies and select the most suitable

and economic one to provide service for us

FAQ:

Q1: Are you a trading company or a manufactory?

A1: We own a factory ourselves, and we can assure the quality we manufactured.

Q2:What's your guarantee or the warranty of the quality if we buy your

machines?

A2:We offer you high quality machines with high quality afterservice. Also we have

one year warranty of the spareparts, free of charge.

Q3: Why choose Jieyang Machinery Co.,Ltd.?

A3: Our products with more than 30% energy saving. Highest Cost effective

environmentally. Excellent pre-sale and after-sale services.